Offshore construction began in 2022 with contractors using specialist vessels to install the offshore infrastructure, beginning with the monopile turbine foundations.

The first phase, Dogger Bank A, is expected to be operational in 2025.

The export cable being pulled towards landfall

The Viking Neptun cable laying vessel near a turbine foundation

Offshore wind farms have two distinct offshore cable requirements, the first being the ‘inter-array’ cable network within the wind farm itself and the other being the subsea ‘export’ cables which bring the generated electricity from the wind farm to shore.

Specialist cable laying vessels are being used to install and bury the subsea cables within the wind farm and along the export cable route to shore.

In July 2024, the project team celebrated an important milestone when the inter-array cable laying was completed within the Dogger Bank A zone. To achieve this more than 200 miles (328 km) of 66KV inter-array cables were successfully installed by our contractors.

The cables were laid by DEME Offshore’s Viking Neptun, with burial works being completed by DEME Offshore’s Living Stone.

The DEME Living Stone cable laying vessel

The inter-array cable network consists of a large number of subsea cables which inter connect the turbines to the offshore HVDC converter platform. The installation and connection of the cables to the turbines requires the use of specialist teams and vessels to:

An offshore platform topside ready for installation

Completing installation of one of the offshore platforms

Our contractors will have built and will install an offshore converter platform within each phase.

Each will take the electricity generated by the turbines and convert it from AC (Alternating Current) to High Voltage Direct Current (HVDC) before the power passes through the adjacent main substations and on to the National Grid.

The first platform, for Dogger Bank A, was installed in April 2023, followed by the second platform in Dogger Bank B in April 2024. The last of the three platforms (for Dogger Bank C) will be installed in 2025.

The innovative offshore platforms have a lean design and are the first unmanned HVDC platforms to be operated from shore and accessed only by a Service Operations Vessel. The platforms will each receive 1.2GW of AC power from the Dogger Bank wind turbines, convert it to DC, and then send it ashore to one of the onshore converter stations in East Riding of Yorkshire or Teesside.

Fitted with Hitachi Energy’s latest generation HVDC converter technology, Dogger Bank will be the first offshore wind project in the UK to use this technology to transmit the electricity produced back to shore, ensuring that the electricity is transmitted efficiently over long distances while minimising losses.

Monopile foundations being installed at Dogger Bank A

The Voltaire installation vessel loaded and leaving the Port of Tyne

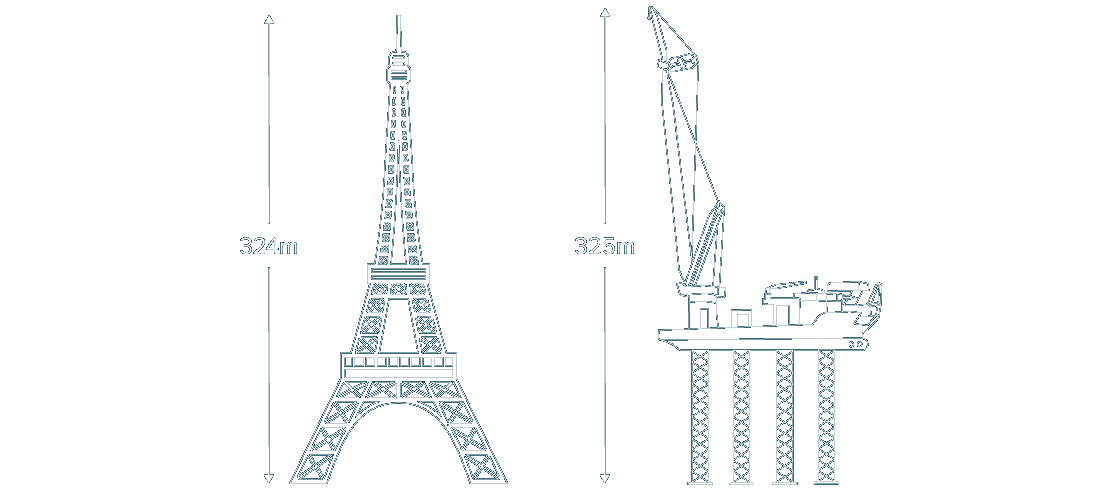

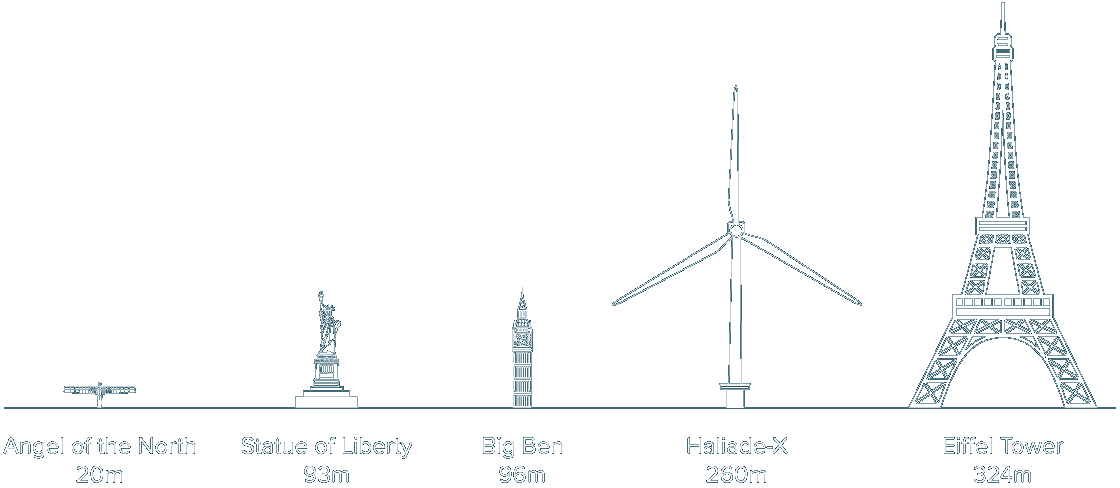

Installation of the wind turbines at Dogger Bank requires the use of specialist installation and support vessels.

The monopile foundations are being installed in the seabed, with a transition piece then fitted, providing a stable and secure platform on to which the turbines can be fixed.

The turbine components, comprising tower sections, nacelles, hubs and blades are delivered to a marshalling and construction facility at Able Seaton Port on the north east coast of England for storage and preparation ahead of being taken to site for installation.

The components are then loaded aboard the ‘Voltaire’, the world’s largest specialist heavy lifting jack up vessel, and shipped to the wind farm for installation and commissioning.

To find out about onshore construction works click here.